Construction

Ventilation and Sound Absorption

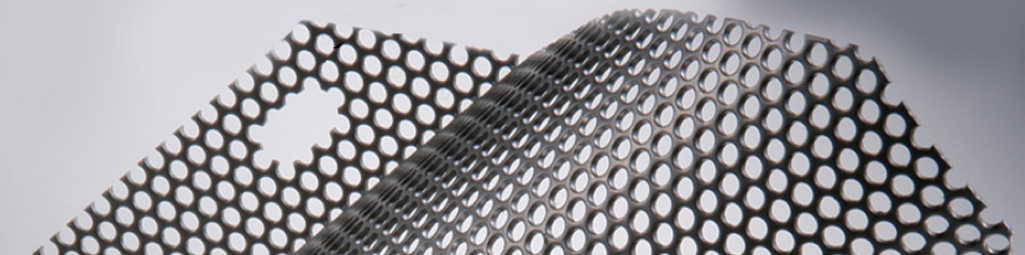

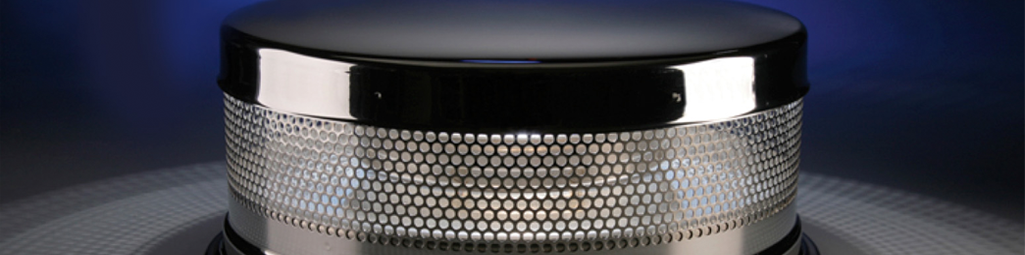

Perforated materials are used in building construction to provide proper ventilation and allow for the passage of moisture in roofs and floor decking. This is especially important in humid environments. Perforation also assists with sound absorption.

McKey Perforating has the equipment, experience and skill to ensure that the perforation process meets the specific requirements of each construction project. Our custom tension equipment allows us to provide tightly wound coils, which can be shipped intact and require less coil handling time.

If your construction project is on a fast track and you need quick turnaround, you can rely on McKey. With plants in Wisconsin, Tennessee, Pennsylvania, Indiana, Texas, and North Carolina, we can provide prompt delivery to keep your project on schedule.

Pre-Engineered Buildings and Modular Homes

Almost any structure can be erected with pre-engineered materials. Pre-engineered buildings are durable, cost-effective, and require less time to construct than conventional building projects. They can also be customized for any use, including housing, commercial, agricultural, institutional and industrial buildings.

McKey Perforating provides perforation for pre-engineered wall and ceiling panels, soffit materials, and architectural finishes. Our perforated materials assist with temperature and moisture control, ventilation and acoustics. They are also a decorative asset to any building – from manufacturing plants to office complexes.

Our precision equipment and highly experienced personnel make the difference in providing tightly wound coil. Pre-painted aluminum and galvanized metal panels are shipped intact and ready for use with less coil handling time.

With six strategically located facilities, you can rely on McKey to provide the quick turnaround you need when working on a shorter construction timeline.

We are a single-source supplier that can assist with fabrication. Secondary operations like leveling, shearing, slitting, lasering, welding, forming and rolling are all performed in-house. Our engineering staff can provide design and technical assistance to customize components to your exact specifications.